Introduction: Where Industrial Progress Meets Certified Quality

India’s manufacturing landscape is booming from skyscrapers and factories to automotive plants and industrial parks, steel is the invisible force powering the nation’s infrastructure.

But what truly defines the strength of steel isn’t just its grade; it’s the consistency, precision, and certification behind every coil.

That’s where Allied Ispat India, an ISO 9001 Certified Trading Coil Manufacturer in India, takes center stage. With a commitment to international standards and years of engineering expertise, Allied Ispat India supplies HR, CR, GP, and PPGI coils that meet the needs of India’s most demanding industries.

From automotive frames and building structures to roll forming and fabrication, Allied’s coils form the foundation of reliability for OEMs, contractors, and distributors across India.

India’s Growing Dependence on Quality Trading Coils

In the post-industrial age, steel isn’t just a material it’s a strategic asset. As the Government of India drives initiatives like Make in India and Smart Cities Mission, the need for high-performance coils has reached new heights.

Manufacturers now seek more than just supply; they seek technical consistency, certified quality, and on-time delivery. Allied Ispat India fulfills this need as a trusted Trading Coil Supplier in India, known for precision-processed coils that perform flawlessly in structural, mechanical, and architectural applications.

Why ISO 9001 Certification Matters in Steel Manufacturing

The ISO 9001 certification represents the global gold standard for quality management systems. It demonstrates that a manufacturer follows rigorous quality assurance processes from procurement to production and dispatch.

For Allied Ispat India, being ISO 9001 certified is not just a formality it’s a business philosophy. Every trading coil manufactured undergoes multi-stage inspection and follows documented procedures ensuring reliability, repeatability, and zero defect tolerance.

How Allied’s ISO 9001 Standards Benefit Clients

- Uniformity in Production: Every coil batch maintains identical mechanical and dimensional properties.

- Transparency: Clients receive traceable product documentation for project compliance and audits.

- Customer Focus: Feedback mechanisms drive continuous process optimization.

- Reduced Rework & Waste: Advanced monitoring ensures consistent output and reduced rejection rates.

This unwavering commitment has earned Allied Ispat India recognition as a Trading Coil Manufacturer in Mumbai trusted by B2B buyers, fabricators, and construction partners nationwide.

Comprehensive Range of Trading Coils Offered by Allied Ispat India

Allied’s diverse product line serves multiple industries that demand precision, durability, and aesthetics. Each coil type is engineered to meet specific functional requirements from heavy structural use to decorative finishes.

1. HR (Hot Rolled) Coils

Used in bridges, frames, machinery, and construction, HR coils are known for toughness, ductility, and weldability. Allied’s HR coils maintain consistent thickness and strength, ideal for load-bearing applications.

2. CR (Cold Rolled) Coils

Preferred by automotive and appliance industries, CR coils offer superior surface finish and tight dimensional tolerance. Allied’s cold-rolled coils are smooth, uniform, and ready for precision fabrication.

3. GP (Galvanized Plain)

Coated with zinc for enhanced corrosion protection, these coils are perfect for roofing, ducting, and outdoor installations. Allied ensures perfect coating adhesion and gloss uniformity.

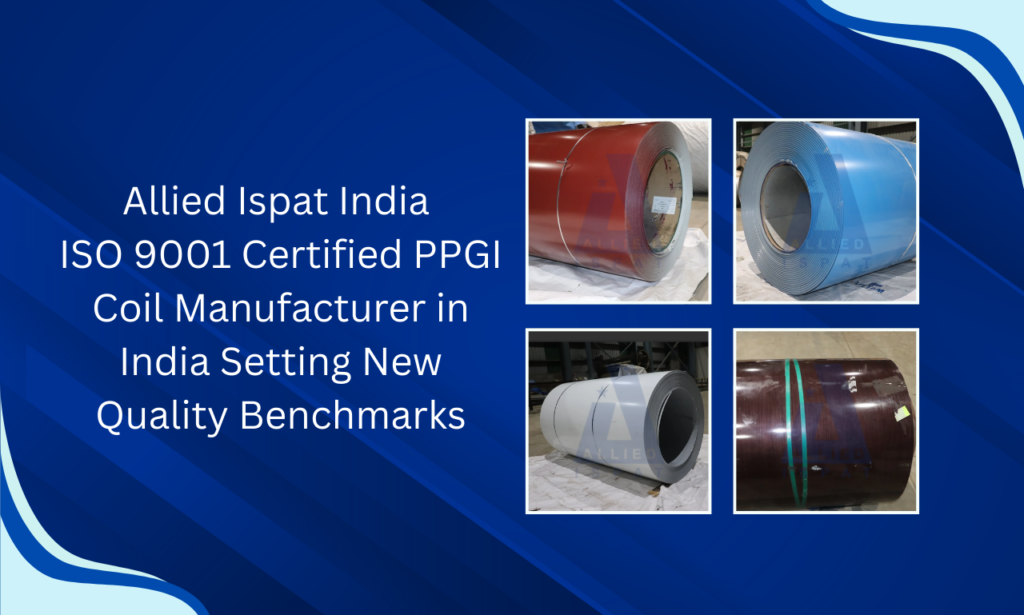

4. PPGI (Pre-Painted Galvanized Iron) Coils

As a reputed PPGI Coil Manufacturer in India, Allied delivers color-coated coils combining aesthetics with durability. Available in multiple shades, PPGI coils are ideal for pre-engineered buildings, facades, and industrial enclosures.

5. Customized Coil Solutions

Allied Ispat India provides coil customization in thickness, width, color, and coating. Whether it’s a one-time project or long-term supply, the company tailors specifications for industrial precision.

The Technology Edge – Where Automation Meets Accuracy

At Allied Ispat India, technology drives quality. The manufacturing facility at MIDC Taloja, Raigad, integrates automation and precision inspection systems to ensure every coil meets global performance standards.

Key Production Strengths

- Advanced Slitting & Cut-to-Length Lines: Achieving precise dimensions and edge quality.

- In-House Testing Laboratory: Evaluating mechanical strength, coating thickness, and surface finish.

- Bulk Warehousing Facilities: Maintaining ready stock for quick delivery across India.

- Efficient Logistics Network: Ensuring timely supply to clients in Mumbai, Pune, Delhi, and other industrial hubs.

This combination of infrastructure and expertise enables Allied Ispat India to maintain its position as a leading Trading Coil Manufacturer in India serving both domestic and export markets.

Customization & Bulk Supply Capabilities

Every industry has unique technical requirements. Allied’s customization capabilities ensure that clients receive coils that perfectly fit their machinery and production process.

Customization Options

- Coil width, thickness, and coating variation.

- Custom color shades for PPGI coils (RAL and non-standard tones).

- Slitting, recoiling, and cut-to-length services.

- Bulk packaging solutions for export or OEM supply.

Whether supplying hundreds of tons to a construction site or smaller quantities to fabricators, Allied Ispat India provides scalable production and logistics designed to meet deadlines with ease.

Sustainability: Engineering with Responsibility

As industries move toward greener production, Allied Ispat India aligns its operations with eco-friendly practices. Sustainability is embedded in the company’s core processes from responsible raw material sourcing to energy-efficient machinery.

Sustainable Manufacturing Practices

- Steel Recycling: Maximizing reuse of metal scrap to reduce waste.

- Energy Optimization: Using efficient rolling and coating systems.

- Non-Toxic Coatings: Ensuring PPGI and GP coils comply with environmental safety norms.

- Water Management: Implementing zero-discharge systems at the Taloja facility.

By balancing industrial growth with environmental consciousness, Allied continues to build a responsible brand trusted by clients who value sustainability as much as strength.

Why Choose Allied Ispat India – A Reliable Trading Coil Partner

Choosing the right supplier can define your production success. Allied Ispat India stands apart with its blend of experience, certification, and customer-centric operations.

1. ISO 9001 Certified Quality Assurance

Every process follows globally recognized standards, ensuring zero-defect output and full traceability.

2. Decades of Experience

With years of industry presence, Allied understands both technical specifications and commercial expectations of industrial clients.

3. Pan-India Distribution Network

From Mumbai to Delhi and Chennai to Pune, Allied’s logistics ensures nationwide supply coverage.

4. OEM Collaboration

The company offers end-to-end material support for OEMs including product selection, documentation, and customized supply models.

5. Timely Delivery

Automated production lines and optimized warehousing help maintain fast turnaround times even for bulk orders.

6. Cost-Effective Pricing

Direct sourcing and in-house manufacturing allow Allied to maintain competitive pricing without compromising quality.

7. Trusted Customer Relationships

Allied builds long-term partnerships through consistency, communication, and post-sales support.

This combination of certification, credibility, and customer focus makes Allied Ispat India one of the most preferred Trading Coil Suppliers in India.

Industries That Depend on Allied’s Trading Coils

Allied Ispat India’s trading coils power multiple industries that demand mechanical precision and aesthetic excellence.

- Construction & Infrastructure: Roofing, cladding, and beam fabrication.

- Automotive Manufacturing: Body panels, doors, and undercarriage components.

- HVAC & Ducting: CR and GP coils used in ventilation and piping systems.

- Roll Forming & Partitions: For shutter slats, door frames, and ceiling sections.

- Consumer Appliances: CR and PPGI coils used in panels, cabinets, and housings.

Each industry relies on Allied’s ability to provide coils that ensure durability, corrosion resistance, and dimensional accuracy.

Global Reach and Export Capability

Beyond domestic markets, Allied Ispat India serves clients across Asia, Africa, and the Middle East. Export-ready packaging, documentation, and logistics coordination make the company a reliable international partner.

From port clearance to containerized shipments, Allied manages every step of the export process, ensuring that overseas buyers receive the same ISO-certified quality delivered across India.

Frequently Asked Questions (FAQs)

1. What is the minimum order quantity (MOQ)?

MOQ varies depending on the coil type and specifications. Allied offers flexible order quantities for both recurring and bulk clients.

2. How soon can orders be delivered?

Lead time generally ranges from 7 to 15 working days, depending on order size, customization, and location.

3. Does Allied provide custom colors or coatings?

Yes. Allied offers custom color coatings and galvanized finishes, including matte, gloss, and textured options for PPGI coils.

4. What certifications support product quality?

Allied operates under ISO 9001:2015 certification, ensuring traceability, documented quality checks, and consistency across every batch.

5. Does Allied serve international clients?

Yes. The company exports trading coils and other steel products globally with full logistic and compliance documentation.

Conclusion: Building India’s Steel Future, One Coil at a Time

Quality in steel manufacturing is not defined by size, but by standards and reliability.

As an ISO 9001 Certified Trading Coil Manufacturer in India, Allied Ispat India continues to lead with innovation, technology, and trust.

With an unmatched focus on precision engineering, customer satisfaction, and sustainable growth, Allied is more than just a supplier it is a strategic partner powering India’s industrial transformation.

Whether you need PPGI coils, HR/CR sheets, or customized GP coils, Allied Ispat India delivers excellence in every batch ensuring your projects are built on a foundation of strength, consistency, and certified quality.

Contact Allied Ispat Mumbai Central

Head Office:

Allied Ispat Pvt. Ltd.

69, Chotta Sonapur, Maulana Shaukat Ali Road, Mumbai - 400008

Phone: +91 98211 77009

Manufacturing Works:

Plot No. C-17/9, MIDC Taloja, Behind Bank of Baroda, Dist. Raigad - 410208

Phone: +91 87790 51606

Email: info@alliedispatindia.com | sales@alliedispatindia.com

Website: https://alliedispatindia.com

Directions: https://maps.app.goo.gl/gyEqxBGcw9jLsYm26

Allied Ispat India – Precision in Every Coil. Reliability in Every Supply.

Your ISO 9001 Certified Trading Coil Manufacturer in Mumbai and Across India.